Rush

by Randy S Keeling

New ● Old ● Vintage ● Antique

Call me at ~ 503-684-5760

11740 SW Gallo, Tigard, Oregon (Near Portland) 97223

In the Incredible Fabulous Pacific Northwest, USA

Below is a list of our most common jobs. If your piece doesn’t fall under a listed catagory, or you’re not sure,

please don’t hesitate to call or email.

We can help!

Since 1975

☆ ☆ ♥ ☆ ☆

We Repair and Recane Furniture and Antiques with:

Rush

We repair furniture, especially chairs with fiber rush cord, a heavy twisted brown craft paper material.

We Repair & Do

- Cane or Caned Seats and Backs, Re-Cane Chairs With Caning. Hand Cane and Press or Machine Caning.

- Rush

- Rawhide

- Danish Cord Weaves – A 3 ply twisted rope material.

- Splint and other types of woven materials on furniture and chairs.

- Wicker Repairs

- Rattan Wrapping

- We also do minor Wood Repairs and regluing.

In Tigard / Portland, Oregon, Near Washington Square.

New – Old – Vintage – Antique

Rush

How do you – I fix or repair chairs with rush seats?

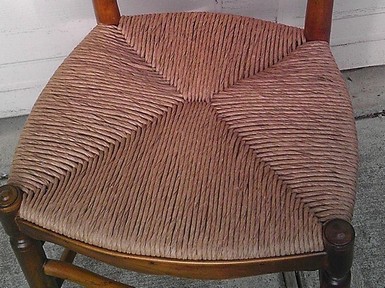

Rush seats have nothing to do with how fast a seat is done! As a matter of fact, they are one of the slowest and time consuming seats to re-weave. A rush seat has a cord-like material wrapped around the four dowels framing the square of a seat; in a pattern I describe as creating four triangles whose points come together in the center. They require a lot of pulling, tugging, and adjusting to complete a beautiful rush seat. The hands get a real workout doing these.

Originally, rush got its name from the Bull Rush Cattail leaves growing around marshy riverbeds or duck ponds. During the fall, the leaves were harvested and stored to dry in barns. They required being turned over every once in a while to keep them from molding and to facilitate even drying. To weave a rush seat, the then dried leaves were soaked in hot water 4-6 hours, and run through an old clothes ringer forcing the air from the cells of the leaves. Next, a leaf would be attached to the side of the chair and 2-3 more leaves are continually added and twisted together throughout the entire seat weaving process. The materials are then spun in and over, under around, and through a pattern until the four triangles are formed and the entire seat area is filled in. As you might imagine, this is an extremely long process!

Fortunately, before the turn of the 1900’s, a man made product was created which looks very similar to natural rush! It is made out of heavy brown craft paper, similar to the color brown paper bags. It comes in long pre-twisted coils weighing 2 to 50 lbs, and is far less labor-intensive to re-rush a seat with. I feel it is much more durable than natural rush, as it does not dry out and become brittle like real rush sometimes does.

Seats like these may last 30-60 years. Of course, there are always people who can wear one out in 10 years. In the olden days, many times between the top and bottom layers of rush old newspapers were stuffed in hollow area creating a firmer or “padded” seat. When I find these, I can hardly wait to carefully extricate these old papers and find dates to give me a good idea of when the chair was rushed! I’ve found some from the late 1800’s and many through 1920’s, 30’s and 40’s. Sometimes even old comics were used, they are a real treat to find! Today we use corrugated cardboard box material which seems to hold its shape and gives a very solid durable seat for many years!

Little care is needed for one of these seats. Initially I tell customers to spray several coats of Scotch Guard Spray on them to help keep the rush from absorbing satins. A simple vacuuming once in a while is about all that is ever necessary. Some people want to stain or color these seats but I caution against this practice as it always seems to wear off, leaving a cracked and splotchy look to the seat. I prefer to leave them natural and allow them to age and color on their own.

Currently Re-cording most Rush Seats costs somewhere between $175.00-$325.00. Some chairs like Windsor Chairs must be taken apart to be re-rushed, which adds some extra costs for taking the chair apart and putting it back together… It can take a long day to do a rush chair! There is a lot of pulling, twisting, packing the cords, cutting and fitting the cardboard to fit into the two layers of rush. My hands get a real workout doing one of these!

This chair below was quite difficult to put on the new rush seat as the arms and all the wood around the seat had to taken off and then re-applied after the new seat was re-rushed. But it sure came out beautiful!

Below is a quite unique little rush chair made to fit perfectly against the wall in a corner. I have only seen this chair once, and then again I saw a chair like it in the movie, “Girl With The Pearl Earring” with Actress Scarlett Johansson.

This one is a very sweet little French chair with a rush seat. It came down with 2 others from and the Tri-City Area of Washington State.